Introduction: The STEM Revolution in 2026 Education

The landscape of American K-12 and higher education is undergoing a fundamental transformation, with science, technology, engineering, and mathematics (STEM) education commanding unprecedented institutional investment and curriculum prioritization. Modern STEM laboratories have evolved beyond the traditional fixed-bench models of past decades, becoming flexible, technology-integrated learning ecosystems designed to accommodate diverse pedagogical approaches—from hands-on experimental chemistry to collaborative maker-space engineering projects.

The global STEM lab furniture market reached $2.97 billion in 2024, reflecting robust demand for innovative, durable laboratory environments. Educational institutions now compete to offer state-of-the-art facilities that attract talented students and support advanced research. This comprehensive guide addresses the fundamental decisions procurement officers, school architects, and STEM coordinators face when designing or upgrading laboratory spaces: How much will it cost? What materials deliver the best return on investment? And how should spaces be configured to maximize learning outcomes while controlling operational expenses?

The challenge is no longer simply furnishing a room with benches and cabinets. Today’s effective STEM labs balance durability with agility, chemical-resistant work surfaces with flexible layouts, and cutting-edge technology integration with sustainable operations. This guide provides the technical specifications, cost frameworks, and strategic design principles that have proven effective across hundreds of U.S. school districts and university systems.

Market Insights: The $8+ Billion STEM Education Infrastructure Boom

Market Growth Trajectory

The U.S. school furniture market currently stands at $6.80 billion (2025) and is projected to expand to $9.35 billion by 2030, growing at a compound annual growth rate (CAGR) of 6.58%. Within this broader category, laboratory furniture and specialized STEM environments represent the fastest-growing segment. The global laboratory furniture market was valued at $1.8 billion in 2024 and is projected to reach $2.8 billion by 2032, expanding at a 7.3% CAGR. More specifically, school and college laboratory segments are expanding at 8.6% CAGR from 2026 to 2033, outpacing general classroom furniture growth.

This accelerating investment stems from multiple drivers: federal STEM education initiatives, state-level science curriculum reforms, post-pandemic facility upgrades, and institutional competition for enrollment in high-performing STEM programs. According to procurement data, the fastest-growing laboratory category is also lifted by public investment in science education, where multilateral programs explicitly fund laboratory upgrades alongside aligned furnishings.

Why STEM Labs Demand Specialized Furniture

Unlike traditional classrooms, science laboratories impose extreme functional demands on physical infrastructure. Workstations must resist acids, bases, organic solvents, and high temperatures simultaneously. Fume hoods and ventilation systems drive energy consumption to levels 4-5 times higher than typical offices. Mobile reconfiguration is increasingly essential, as instructors transition between lecture-based instruction, small-group experimentation, and large-cohort demonstrations within the same teaching period.

The shift toward modular and ergonomic laboratory furniture reflects this complexity. Unlike traditional fixed furniture, modular designs allow labs to adapt layouts quickly in response to changing research needs and teaching methodologies. This adaptability has become a standard procurement requirement in K-12 and higher education competitive bidding processes.

The Price of Innovation: Understanding STEM Lab Costs

Construction and Build-Out: The Per-Square-Foot Framework

The first decision point for any institution is scope and scale. Laboratory construction costs vary dramatically based on complexity, location, and equipment specifications.

Baseline construction costs:

- Modern lab construction: $350–$1,300 per square foot

- University tech and science lab facilities: $760 per square foot

- Research institution fit-out (life sciences): $837 per square foot average; high-tech facilities exceed $1,230 per square foot

For a typical high school science wing with 3,000 net assignable square feet (NASF), construction costs range from $1.05 million (at $350/sqft) to $3.9 million (at $1,300/sqft). These figures include structural elements, HVAC systems, plumbing, electrical, and hazardous-materials handling infrastructure.

Equipment, Casework, and Furniture Costs: The $200K–$1M Range

Initial laboratory setup for educational institutions typically falls into three categories:

| Lab Scale | Square Footage | Equipment & Furniture Budget | Total Project Cost |

|---|---|---|---|

| Small (High School Section) | 2,000 | $80K–$100K | $200K–$400K |

| Medium (University Teaching Lab) | 5,000 | $200K–$250K | $400K–$800K |

| Large (Research Complex) | 10,000+ | $400K–$600K+ | $750K–$1M+ |

Equipment and casework typically represent 40% of total project costs, with construction/installation comprising 35%, technology integration 15%, and compliance/testing 10%.

Chemistry labs—the most equipment-intensive discipline—typically require:

- $185,000–$220,000 for specialized casework, plumbing, and exhaust systems

- Fume hoods: $10,000–$25,000 per unit (each lab typically has 4–8)

- Gas delivery systems: $15,000–$50,000 depending on complexity

- Eyewash stations, safety showers, fire suppression: $8,000–$15,000

- Emergency protocols and signage: $3,000–$5,000

Physics and engineering labs require less complex plumbing but often demand vibration-resistant, heavy-duty steel benches ($300–$600 per linear foot installed) to accommodate sensitive instrumentation.

STEM Lab Cost Breakdown by Size Category

Operating Costs: The Hidden Expense of Energy and Maintenance

Many procurement officers focus exclusively on capital costs, overlooking the 20+ year operational burden. Laboratory energy consumption is the critical variable.

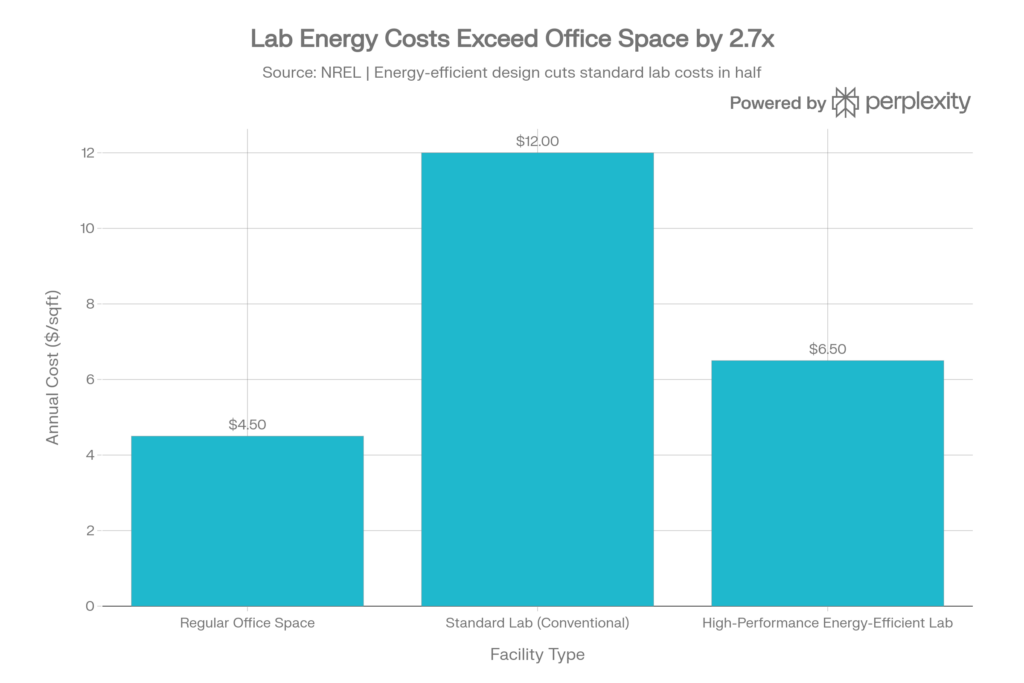

Energy consumption reality:

- A single open fume hood consumes as much energy as 3.5 homes in 24 hours.

- U.S. laboratory facilities operate at 30–100 kilowatt-hours per square foot annually, compared to 15.9 kWh/sqft for office buildings (approximately 2.5x higher).

- Annual operating cost of U.S. fume hoods alone: $4.2 billion.

For a 5,000-sqft laboratory facility with conventional fume hoods, annual energy costs typically range from $30,000 to $80,000, depending on climate zone and operating intensity. Over a 25-year facility life, this accumulates to $750,000–$2 million in energy expenses alone.

Laboratory vs. Office Space: Annual Energy Costs Comparison

Maintenance and consumables (annual):

- Chemical inventory management and safe disposal: $5,000–$15,000

- Equipment servicing, recalibration, repairs: 5–15% of equipment value annually

- Cleaning, decontamination supplies: $2,000–$8,000

- Staff training and safety certification: $3,000–$7,000

Total annual operating costs typically range from $40,000 to $150,000 for a 5,000-sqft facility, depending on discipline intensity and utilization rates.

Material Science: Choosing Surfaces That Last 25 Years

Selecting the correct surface material is the single most critical decision in lab design. Work surfaces must balance four competing demands: chemical resistance, temperature stability, durability, and cost-efficiency. The wrong material choice can result in complete casework replacement within 5–10 years; the right selection ensures performance over 25+ years.

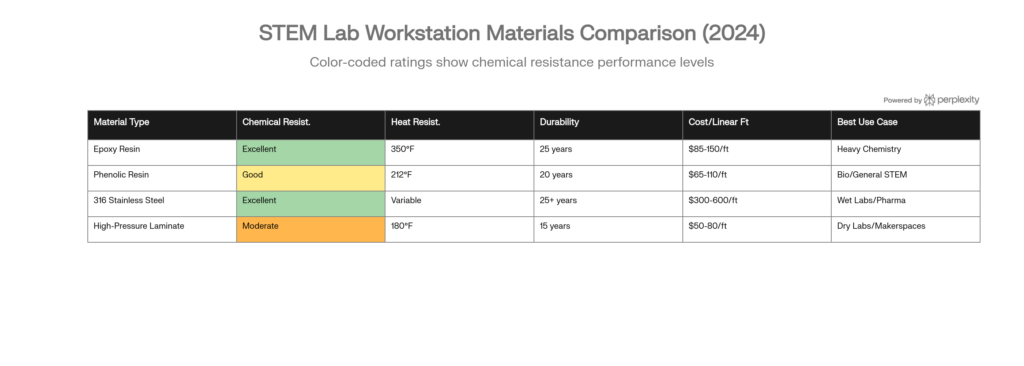

The Four Material Workhorses

Epoxy Resin Surfaces

- Chemical resistance: Exceptional; resists acids, bases, and most organic solvents up to 350°F

- Best use: Heavy chemistry, organic synthesis labs, clinical diagnostics

- Cost: $85–$150 per linear foot installed

- Durability: 25 years

- Maintenance: Requires periodic sealing; resists staining better than phenolic

- Trade-off: Most expensive upfront; highest chemical resilience

Phenolic Resin Surfaces

- Chemical resistance: Good for general laboratory work; lighter and more cost-effective than epoxy

- Best use: General biology labs, introductory chemistry, physics prep areas

- Cost: $65–$110 per linear foot installed

- Durability: 20 years

- Maintenance: More prone to staining than epoxy; requires more frequent cleaning

- Trade-off: Lower cost; adequate for non-aggressive chemical environments

316 Stainless Steel Casework

- Chemical resistance: Excellent; superior to 304 grade; includes 2–3% molybdenum for chloride and acid resistance

- Best use: Wet labs, pharmaceutical labs, fume hood interiors, coastal facilities

- Cost: $300–$600 per linear foot (casework fully installed)

- Durability: 25+ years; can be refurbished and recycled

- Maintenance: Requires passivation treatment initially; benefits from regular stainless-steel cleaner

- Trade-off: Highest cost but unmatched longevity; “marine grade” protection against harsh solvents

- Marine vs. Standard Note: 316L (low-carbon) variant eliminates chromium carbide precipitation, preventing intergranular corrosion in welded assemblies

High-Pressure Laminate (HPL)

- Chemical resistance: Moderate; suitable for non-chemical environments

- Best use: Dry labs, maker-spaces, computer labs, physics classrooms

- Cost: $50–$80 per linear foot installed

- Durability: 15 years

- Maintenance: Susceptible to water damage if not sealed; cannot tolerate significant heat

- Trade-off: Most economical; adequate for controlled, non-aggressive environments

STEM Lab Materials Comparison: Specifications & Cost Analysis

The 304 vs. 316 Stainless Steel Decision: Grade Selection Matters

Stainless steel grade selection is a recurring point of confusion in procurement. Both grades contain 18% chromium and 8–10% nickel, making them highly corrosion-resistant in benign environments. The critical differentiator is molybdenum content.

Grade 304 is appropriate for dry labs, general instrument workstations, and storage areas where liquid exposure is limited. Grade 316 is mandatory for environments involving chlorinated solutions, strong acids, or aggressive cleaning protocols (e.g., pharmaceutical manufacturing, clinical labs). Using 304 in high-chloride environments results in visible corrosion within 12–18 months.

Strategic Layouts: From Fixed Benches to Intelligent Mobile Stations

Mobile STEM Lab Workstations with Integrated Storage and Utility Connections

The Shift from Static to Dynamic

The traditional “fixed bench, two stools per station” laboratory model has become functionally obsolete. Contemporary STEM pedagogy demands spaces that transition seamlessly from instructor-led demonstrations to small-group collaborative work to independent student investigation—often within a single 90-minute class period.

Modern layout strategies address this through three complementary approaches:

Mobile Lab Stations: The Flexibility Premium

Heavy-duty mobile workstations, equipped with locking casters, allow instructors to reconfigure the entire lab layout in minutes. Key specifications:

- Caster rating: Load capacity of 50–150 lbs per caster; typical 4-caster stations support 500–2,000 lbs

- Locking mechanism: Pneumatic or mechanical locks ensure stability during experimentation

- Work surface height: 30–36 inches (accommodating seated and standing work); height-adjustable models ($800–$2,000 additional per station) support ADA accessibility and reduce operator fatigue

- Footprint options: 2-student stations (24″×48″) through 4-student configurations (48″×60″)

- Storage integration: Under-bench shelving and vertical cable management for gas, data, and power lines

Cost: $2,500–$5,000 per mobile workstation (complete assembly with work surface and storage).

Mobile configurations increase effective room utilization by 30–50%, as the same physical space can transition from traditional rows (lecture facilitation) to clustered groups (collaborative work) to open floor (large-scale demonstrations) without structural modifications.

Reach Zone Ergonomics: The 15–18 Inch Standard

One of the most overlooked design principle in laboratory planning is the “reach zone”—the distance from the user’s torso within which frequently-accessed materials should be positioned. Research demonstrates that placing reagents, tools, and equipment within 15–18 inches of the worker minimizes strain, reduces spill incidents, and improves efficiency.

Effective reach-zone design requires:

- Primary work surface: Immediately in front of user (0–6 inches from body)

- Secondary reach zone: Tools and frequently-used chemicals (6–18 inches)

- Storage zone: Backup supplies and less-frequent materials (18–36 inches)

- Archive zone: Seasonal or archived equipment (beyond 36 inches; typically wall-mounted shelving)

When designing mobile or fixed workstations, the most frequently-used items—safety goggles, gloves, standard reagents—must be accessible without reaching beyond arm’s length. Workstations that violate this principle lead to increased incident rates and user complaints within the first semester.

Shared Lab Concepts: Optimizing Capacity and Utilization

Large universities and well-funded high schools increasingly adopt “shared lab” models, where a single state-of-the-art facility serves multiple departments or course sections on rotating schedules. Rather than each department maintaining a dedicated 2,000-sqft lab at 40% utilization, shared facilities operate at 75%+ utilization.

Implementation requirements:

- Modular furniture: Complete casework and equipment must be portable (weight <100 lbs per module) or quickly reconfigurable

- Protocol standardization: All departments using the shared space must adopt compatible safety and waste-management procedures

- Scheduling software: Facilities booking systems with real-time availability and equipment-reservation tracking

- Quick-change infrastructure: Gas, electrical, and data connections use standardized quick-couplers ($50–$200 per connection) rather than fixed hardwiring

Shared lab models reduce per-student infrastructure cost by 25–40% while maintaining equipment quality and safety standards.

Material Innovation in 2026: Sustainable Lab Design Without Compromising Performance

The Green Lab Movement: Cost Savings Through Efficiency

Sustainable laboratory design has evolved from a marketing differentiator to a standard procurement requirement. Universities and school districts increasingly mandate LEED certification, carbon-neutral operations targets, and circular-economy principles for facility renovations.

Energy efficiency gains translate directly to cost savings:

- High-performance fume hoods (Variable Air Volume systems): 40% energy reduction compared to constant-air-volume models

- Ductless fume hoods: 90% energy reduction (suitable for non-hazardous laboratory work)

- LED laboratory lighting: 75% energy reduction vs. conventional fluorescent

- Green labs reduce operational costs by 30–50% over facility lifetime

- LEED-certified labs achieve $0.50/sqft annual savings in operating costs

Sustainable material choices:

- Stainless steel: 100% recyclable; supports end-of-life material recovery

- Recycled composite materials: Phenolic casework increasingly manufactured from recycled content (15–30%)

- Low-VOC finishes: Eliminate volatile organic compounds; improve indoor air quality without performance trade-offs

- FSC-certified wood: Where wood casework is used, certification ensures responsible forestry

- Modular prefabrication: Uses 30% fewer materials compared to traditional on-site construction

ROI on sustainability investments:

- Variable-air-volume fume hoods: 1–2 year payback

- High-performance HVAC systems: 3–5 year payback

- LED conversion: 2–3 year payback

For a 5,000-sqft facility operating 24/7 (as typical university research labs do), transitioning from conventional to high-performance fume hoods alone generates $15,000–$25,000 annual energy savings, eliminating the incremental cost premium within 2–3 years.

Smart Lab Integration: IoT and Facility Management

The “Internet of Things” (IoT) is transforming laboratory operations through real-time monitoring and predictive maintenance. Contemporary STEM lab design increasingly incorporates:

- Humidity and temperature sensors: Maintain precise conditions for sensitive experiments; alert users when environmental parameters drift outside safe ranges

- Fume hood airflow monitors: Verify hood operation in real-time; prevent accidental operation of non-functional equipment

- Energy consumption dashboards: Track real-time electrical and thermal energy use; identify inefficiencies

- Asset tracking: RFID tags on expensive equipment reduce loss and improve inventory accuracy

- Occupancy sensors: Coordinate HVAC cycling with actual room usage; disable ventilation during unoccupied periods

Cost: IoT sensor networks and facility management software integrate into modern lab furniture at $3,000–$8,000 per 2,500-sqft facility. Institutions report 5–15% energy reductions through behavioral change alone (operators conscious of real-time consumption adjust practices).

Technology Integration: The 2026 Standard for Modern STEM Labs

IoT-Enabled Smart Workstations

The newest generation of laboratory workstations integrates sensors, power management, and data infrastructure into intelligent networked systems. Rather than treating furniture as inert surfaces, contemporary design treats the entire workstation as a data-collection and facility-management asset.

Smart workstation features:

- Integrated power management: Outlets with programmable scheduling; USB and wireless charging ports

- Data connectivity: Ethernet jacks, WiFi access points, and optional 5G cellular connectivity built directly into work surface modules

- Environmental monitoring: Humidity, temperature, and air quality sensors with real-time display and cloud logging

- Equipment locking: RFID-based access controls preventing unauthorized use of high-cost instrumentation

- Occupancy detection: Automatic HVAC and ventilation cycling based on room presence

Cost: Smart workstations cost $800–$1,500 more per station than conventional furniture (10–25% premium), but generate operational savings through energy reduction and reduced equipment loss/theft.

Modular Raceways for Gas, Vacuum, and Data

Modern chemistry and biology labs require multiple utility connections: natural gas, vacuum, deionized water, compressed air, nitrogen, electrical, and data. Traditional hardwired installations require 4–8 week renovation timelines to modify.

Contemporary practice uses modular, tool-free raceway systems that permit relocation without wall-breaking. Key advantages:

- Reconfiguration time: 2–4 hours vs. 4–8 weeks for conventional hardwiring

- Cost: $100–$200 per linear foot vs. $500–$1,000 for hardwired installations

- Flexibility: Add, remove, or modify connections as course requirements evolve

- Scalability: Additional workstations can be provisioned without structural modifications

For schools planning to refresh laboratory configurations every 5–7 years (following curriculum updates or pedagogical shifts), modular infrastructure reduces renovation costs by 40–60%.

Expert Advisory: Managing Hidden Lifecycle Costs

Energy Consumption: The $4 Billion Annual Drain

While procurement teams focus on equipment costs, operating costs often exceed capital investment within 10–15 years. Energy consumption is the primary culprit.

A typical 5,000-sqft chemistry lab with 8 conventional fume hoods operating 12 hours daily costs approximately $60,000 annually in energy. Over a 25-year facility life, this accumulates to $1.5 million—exceeding the original construction investment.

Mitigation strategies:

- Prioritize variable-air-volume (VAV) fume hoods; 40% energy reduction justified by 2-year payback

- Install occupancy sensors triggering HVAC scheduling; prevents 24-hour operation during unoccupied periods

- Upgrade to LED lighting with occupancy control; 75% energy reduction

- Implement real-time energy dashboards; behavioral awareness drives 5–15% consumption reduction

- Conduct annual energy audits identifying sub-optimal equipment performance

Inventory and Maintenance: The 5–15% Annual Burden

Institutions consistently underestimate ongoing maintenance and consumable costs. Chemical inventory tracking alone—ensuring safe storage, preventing expiration, and managing hazardous-waste disposal—requires dedicated staff and systematic protocols.

Typical annual maintenance allocations:

- Equipment servicing and recalibration: 5–10% of equipment replacement value

- Consumable supplies (gloves, cleaning materials, safety equipment): $5,000–$15,000

- Casework repairs and refinishing: $3,000–$8,000 (increasing with age and use)

- Staff training and certification: $3,000–$7,000

- Total: 8–15% of initial capital investment annually

For a $500,000 facility, this implies $40,000–$75,000 annual maintenance costs—often overlooked during budget planning.

Material Wastage and Improper Storage

Chemical storage generates hidden financial drains. Poorly organized storage areas lead to:

- Redundant purchasing: Unknown inventory leads to duplicate orders ($10,000–$20,000 annually)

- Expiration and waste: Deteriorated chemicals requiring hazardous-waste disposal ($5,000–$15,000)

- Space inefficiency: Disorganized storage consumes 20–30% additional square footage

- Safety incidents: Incompatible chemicals in proximity risk reactions and contamination

Implementing inventory management systems, establishing clear storage protocols, and conducting quarterly audits eliminates 30–50% of wastage, generating $10,000–$25,000 annual savings.

Procurement Strategy: From RFP to Installation

Budget Development and Total Cost of Ownership

School districts and universities increasingly adopt total-cost-of-ownership (TCO) frameworks rather than focusing exclusively on purchase price. TCO analysis includes:

- Capital costs: Equipment, casework, installation, project management

- Energy costs: 25-year operational energy consumption

- Maintenance costs: Repairs, replacements, consumables

- Opportunity costs: Downtime, facility unavailability during renovations

For a typical $500,000 laboratory project:

- Capital: $500,000 (Year 0)

- Energy: $50,000/year × 25 years = $1,250,000

- Maintenance: $35,000/year × 25 years = $875,000

- Total cost of ownership: ~$2,625,000

Reducing annual energy costs by $15,000 through efficiency upgrades (costing $40,000 additional capital) generates $375,000 savings over 25 years—a 9.4x ROI. This framework demonstrates why specification decisions (e.g., VAV vs. conventional fume hoods) should prioritize lifecycle cost, not purchase price.

Vendor Selection Criteria Beyond Price

The National Institute of Standards and Technology reports that 67% of laboratory renovations exceed initial budgets due to inadequate scope definition during RFP development. Effective vendor evaluation should assess:

| Evaluation Criterion | Weight | Key Questions |

|---|---|---|

| SEFA 8 Certification | 25% | Are all casework components independently certified? What is testing documentation? |

| Material Specifications | 20% | Are materials specified by grade? (e.g., 304 vs. 316 stainless steel; epoxy vs. phenolic) |

| Energy Efficiency | 15% | Does specification include VAV fume hoods? What is projected energy consumption? |

| Timeline & Logistics | 15% | What is installation schedule? Are temporary lab spaces available during renovation? |

| Post-Installation Support | 15% | What warranty coverage applies? What is vendor response time for service calls? |

| Sustainability Credentials | 10% | Is casework recyclable? What material certifications apply? (FSC, Cradle-to-Cradle, etc.) |

Request for Proposal Development: Detailing Specifications

Effective RFPs specify materials, dimensions, and performance standards rather than permitting vendor substitution. Example:

Poor specification: “Supply laboratory benches with stainless steel work surfaces suitable for chemistry instruction.”

Effective specification: “Supply mobile laboratory workstations meeting SEFA 8-M standards, configured as follows: (1) Stainless Steel Grade 316 work surface, 1.5-inch thickness, minimum dimensions 48″L × 30″D; (2) Epoxy resin backup surface option for budget-constrained configurations; (3) Mobile casters with minimum 1,000-lb load capacity, pneumatic locking mechanism; (4) Under-bench storage with modular raceway for gas, vacuum, and data connections; (5) Certification: Provide SEFA 8-M test report from accredited laboratory; (6) Lead time: 10–12 weeks; (7) Installation: Vendor responsible for on-site assembly, leveling, and utility connection.”

Itemized specifications generate 12–18% better pricing and prevent post-purchase disputes regarding material substitution or quality.

Emerging Trends: Looking Beyond 2026

Modular and Prefabricated Laboratories

Rather than building labs on-site, institutions increasingly purchase fully-assembled, prefabricated laboratory modules that arrive ready for installation. These modular systems offer:

- Faster deployment: 4–6 week installation vs. 16–20 weeks for traditional construction

- Reduced material waste: Factory construction uses 30% fewer materials vs. on-site building

- Quality consistency: Modules manufactured in controlled environments with consistent tolerances

- Scalability: Add additional modules as enrollment or research programs expand

- Relocatability: Prefab modules can be reconfigured or relocated if institutional needs change

Cost: Slight premium (5–10%) offset by reduced construction timeline and labor costs.

AI-Driven Lab Management and Predictive Maintenance

Artificial intelligence systems are beginning to optimize laboratory operations in real-time. Emerging applications include:

- Predictive maintenance: AI monitors equipment performance, predicting failures 2–4 weeks before they occur

- Energy optimization: Machine learning algorithms optimize HVAC scheduling based on occupancy patterns and weather forecasts

- Safety compliance: Automated monitoring ensures fume hoods, eyewash stations, and safety equipment remain operational

- Inventory management: AI tracks chemical usage patterns, predicting reorder needs and flagging approaching expiration dates

Currently in early adoption among R&D institutions; K-12 implementation anticipated within 3–5 years as costs decline.

Hybrid Learning Laboratories

The post-pandemic educational environment has validated hybrid learning models combining in-person experimentation with remote observation and virtual collaboration. Forward-looking lab designs incorporate:

- Integrated video documentation: Cameras positioned to capture workstation-level detail for remote viewers

- Digital projection: Displays permitting remote instructors to annotate experiments in real-time

- Remote-capable instruments: IoT-connected sensors streaming data to cloud platforms accessible by remote students

- Collaborative platforms: Shared digital workspaces permit distributed student teams to analyze data, manage protocols, and document findings

These capabilities demand additional technology infrastructure ($20,000–$50,000 per lab) but enable schools to reach rural and underserved populations through distance STEM instruction.

Conclusion: Strategic Priorities for 2026 Laboratory Planning

Modern STEM laboratory design balances competing demands: durability against flexibility, specialization against versatility, initial cost against lifecycle value. Effective procurement strategies prioritize:

For K-12 Administrators

- Prioritize flexibility: Mobile workstations and modular infrastructure accommodate evolving curricula without structural renovation

- Standardize on materials: Specify 304 stainless steel (cost-effective) or epoxy resin (superior durability) across all labs; avoid mixing materials that complicate replacement purchasing

- Invest in energy efficiency: VAV fume hoods and occupancy controls generate 6–10 year payback; justify premium pricing through TCO analysis

- Plan for 25-year lifespan: Durability and maintainability should trump lowest purchase price

For University Facility Planners

- Specify SEFA 8 compliance: Non-negotiable for research labs; ensures structural integrity and chemical resistance

- Adopt stainless steel Grade 316: Marine-grade corrosion resistance justifies 15–20% cost premium through reduced maintenance

- Implement smart infrastructure: IoT sensors and real-time monitoring optimize energy and asset utilization

- Design for shared utilization: Multi-departmental access increases facility ROI by 40–60%

For All Institutions

- Conduct total-cost-of-ownership analysis: 25-year lifecycle costs typically 4–5x capital investment; energy, maintenance, and operational expenses dominate

- Develop comprehensive RFPs: Detailed specifications prevent cost overruns and vendor disputes

- Partner with research-driven vendors: Steelcase Learning, Herman Miller, and specialized laboratory furniture manufacturers have published research validating design effectiveness

- Plan sustainability early: Green lab certifications and energy-efficient systems deliver 30–50% operational cost reductions

The $8+ billion STEM education infrastructure boom reflects genuine institutional commitment to science education excellence. Procurement officers who balance rigorous specification standards, lifecycle cost analysis, and flexibility priorities will deliver laboratories supporting transformational learning experiences for decades to come.