Hotel furniture selection represents one of the most critical decisions in hospitality design, directly impacting guest satisfaction, operational efficiency, and long-term profitability. Unlike residential furniture, commercial hotel furniture must withstand intensive daily use while maintaining aesthetic appeal and functional performance across diverse guest needs. Understanding the fundamental differences between commercial-grade hospitality furniture and residential alternatives enables hoteliers, designers, and procurement professionals to make informed investment decisions that balance durability, style, and cost-effectiveness.

The hotel furniture industry has evolved significantly, with properties investing between $15,000 to $50,000 per room in FF&E (Furniture, Fixtures, and Equipment) to create distinctive guest experiences . This substantial investment reflects the strategic importance of furniture in brand differentiation, guest retention, and revenue optimization. Commercial hospitality furniture must comply with stringent safety standards, accommodate high-traffic usage patterns, and support diverse operational requirements while reflecting brand identity and design vision.

This comprehensive guide examines four essential aspects of hotel furniture categories: fundamental differences between commercial and residential furniture applications, material specifications and durability requirements for hospitality environments, procurement strategies and cost considerations, and maintenance protocols for maximizing furniture lifespan. Each section provides actionable insights backed by industry expertise and real-world examples to help you navigate the complex landscape of hospitality furniture selection.

Understanding Commercial vs. Residential Furniture Applications

Commercial hotel furniture differs fundamentally from residential alternatives in design philosophy, construction methods, and performance requirements. Commercial-grade furniture prioritizes durability, safety compliance, and operational efficiency over purely aesthetic considerations, though modern hospitality design successfully integrates both functional and visual excellence.

Durability requirements for hotel furniture far exceed residential standards, with commercial pieces designed to withstand 10-20 times more usage cycles than home furniture. Hotel guest room furniture experiences constant use from hundreds of different occupants annually, requiring materials and construction methods that maintain structural integrity and visual appeal despite intensive wear patterns.

Safety compliance represents a non-negotiable aspect of commercial hospitality furniture, with all pieces required to meet fire safety standards such as CAL 117-2013 for upholstery and ASTM guidelines for structural components. Fire-rated materials and flame-resistant treatments ensure guest safety while meeting insurance and regulatory requirements that residential furniture typically does not address.

Table 1: Commercial vs. Residential Furniture Comparison

| Aspect | Commercial Hotel Furniture | Residential Furniture |

|---|---|---|

| Usage Intensity | 10-20x daily usage cycles | Moderate family use |

| Safety Standards | CAL 117, ASTM compliance required | Minimal safety requirements |

| Material Specifications | Commercial-grade, fire-rated | Standard household materials |

| Warranty Coverage | 5-10 years structural | 1-3 years typical |

| Cost Range | $800-$3,500 per piece | $200-$800 per piece |

| Replacement Cycle | 7-15 years | 10-20 years |

Functional design considerations in hotel furniture include space optimization, multi-purpose capabilities, and ease of maintenance. Hotel room furniture must maximize limited square footage while providing essential guest amenities, leading to innovative designs such as beds with integrated storage, desks that convert to dining surfaces, and seating with hidden compartments.

Brand alignment requirements for commercial hotel furniture necessitate cohesive design themes that reinforce property identity while appealing to target demographics. Luxury hotel furniture emphasizes premium materials and sophisticated aesthetics, while budget hotel furniture focuses on durability and cost-effectiveness without sacrificing guest comfort.

Maintenance accessibility represents a crucial design factor in commercial hospitality furniture, with pieces engineered for easy cleaning, repair, and component replacement. Hotel housekeeping staff require furniture that facilitates efficient room turnover while maintaining sanitary standards, influencing material selection and construction details.

Case Study: Mowbray Court Hotel Transformation

The Mowbray Court Hotel in Earl’s Court underwent a complete furniture transformation from a 2-star to 4-star property, requiring custom-built wardrobes, bespoke shelving, and commercial-grade upholstery across 125 bedrooms. The project utilized commercial hospitality furniture specifically designed for the building’s Victorian character while meeting modern safety and durability standards.

Material Specifications and Durability Standards

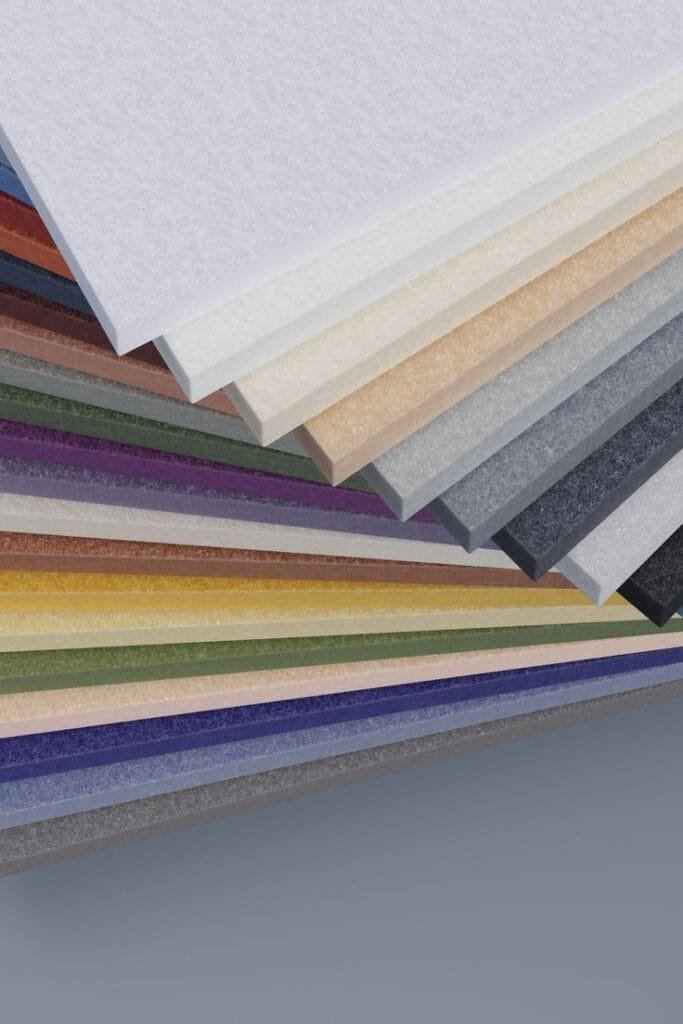

Commercial-grade materials form the foundation of successful hotel furniture programs, with specific material properties required to withstand intensive hospitality environments. Solid hardwoods such as oak, maple, and ash provide exceptional structural integrity for high-traffic applications, while engineered wood products with high-pressure laminates offer cost-effective durability for budget-conscious properties.

Fire-rated laminates represent essential safety components in hotel furniture construction, with premium high-pressure laminates capable of withstanding direct flame exposure at 1100°C for 30 seconds without ignition. These materials exceed standard abrasion resistance requirements by 100%, ensuring long-term performance in commercial applications.

Table 2: Hotel Furniture Material Performance Standards

| Material Category | Durability Rating | Fire Safety | Maintenance Level | Cost Factor |

|---|---|---|---|---|

| Solid Hardwood | 9/10 | Class A with treatment | Medium | High |

| High-Pressure Laminate | 8/10 | Inherently fire-rated | Low | Medium |

| Commercial Vinyl | 7/10 | Class A compliant | Very Low | Low |

| Engineered Quartz | 9/10 | Non-combustible | Low | High |

| Powder-Coated Metal | 8/10 | Naturally fire-resistant | Low | Medium |

Upholstery specifications for commercial hotel seating require performance fabrics with minimum 50,000 double-rub counts for durability, antimicrobial treatments for hygiene, and stain-resistant finishes for maintenance efficiency. Commercial-grade leather provides superior longevity despite higher initial costs, often lasting 12-15 years with proper care protocols.

Hardware specifications for hotel furniture include heavy-duty drawer slides, commercial-grade hinges, and reinforced joinery systems designed to withstand constant use without failure. Powder-coated finishes on metal components provide corrosion resistance essential for coastal properties and high-humidity environments.

Environmental considerations influence material selection through sustainability requirements and indoor air quality standards. FSC-certified lumber, low-VOC finishes, and recyclable materials address growing environmental consciousness among travelers while meeting green building certification requirements.

Quality assurance protocols for commercial hotel furniture include stress testing, fire safety verification, and durability validation through accelerated aging processes. Third-party certifications such as GREENGUARD Gold ensure materials meet strict chemical emissions standards for indoor environments.

Case Study: Six Senses Southern Dunes Hotel

The Six Senses Southern Dunes Hotel project exemplified premium custom hotel furniture manufacturing, utilizing sustainable materials sourced globally while meeting strict fire safety and durability standards. Every piece underwent rigorous quality assurance protocols to ensure 10+ year lifespans in the demanding Saudi Arabian climat.

Procurement Strategies and Investment Considerations

Hotel furniture procurement requires sophisticated planning that balances immediate capital requirements with long-term operational benefits. FF&E budgeting typically represents 8-12% of total project costs for new hotel developments, with luxury properties investing $30,000-$50,000 per room in furniture and fixtures.

Procurement timeline planning begins 12-18 months before hotel opening, allowing sufficient time for design development, manufacturing, and delivery coordination. Early procurement enables better pricing negotiations and reduces risk of delays that could impact opening schedules.

Table 3: Hotel Furniture Procurement Timeline and Budget Allocation

| Hotel Category | Per Room Budget | Procurement Start | Lead Time | Key Focus Areas |

|---|---|---|---|---|

| Luxury | $35,000-$50,000 | 18 months prior | 16-20 weeks | Custom design, premium materials |

| Upscale | $20,000-$35,000 | 15 months prior | 12-16 weeks | Brand compliance, durability |

| Midscale | $12,000-$20,000 | 12 months prior | 8-12 weeks | Cost efficiency, standardization |

| Economy | $8,000-$12,000 | 10 months prior | 6-10 weeks | Basic functionality, value pricing |

Supplier selection criteria prioritize commercial hospitality experience, quality certifications, delivery reliability, and post-installation support capabilities. Established hospitality furniture manufacturers offer 5-10 year warranties on structural components and maintain replacement parts inventory throughout furniture lifecycles.

Cost optimization strategies include bulk purchasing negotiations, standardized design elements, and strategic timing of procurement activities. Volume commitments across multiple properties enable significant cost savings while maintaining quality standards.

Financing options for hotel furniture procurement include traditional bank financing, equipment leasing, and supplier financing programs. Leasing arrangements reduce initial capital requirements while providing flexibility for periodic updates and technology integration.

Quality control processes throughout procurement include pre-production samples, factory inspections, and delivery verification procedures. Third-party quality assurance services ensure compliance with specifications and reduce risk of costly replacements.

Case Study: Conscious Hotels Amsterdam

Conscious Hotels demonstrates innovative sustainable procurement strategies, utilizing furniture made from compressed recycled materials including used hotel linens for lobby storage units and recycled yogurt cups for dining tables. This approach reduced procurement costs by 30% while achieving superior environmental credentials.

Maintenance Protocols and Lifecycle Management

Preventive maintenance programs significantly extend hotel furniture lifespan while preserving aesthetic appeal and guest satisfaction. Systematic maintenance protocols can extend furniture lifecycles by 40-60% compared to reactive maintenance approaches, directly impacting long-term profitability.

Daily maintenance routines performed by housekeeping staff focus on proper cleaning techniques, damage prevention, and basic inspection protocols. Commercial-grade cleaning products specifically formulated for hospitality applications protect furniture finishes while maintaining sanitary standards required for guest safety.

Table 4: Hotel Furniture Maintenance Schedule and Cost Impact

| Maintenance Type | Frequency | Staff Required | Time Investment | Annual Cost Savings |

|---|---|---|---|---|

| Daily Cleaning | Every room turnover | Housekeeping | 10 min/room | $2,000-$3,000 |

| Weekly Inspection | All public areas | Maintenance | 2 hours/week | $5,000-$8,000 |

| Monthly Deep Clean | Guest rooms | Professional service | 1 hour/room | $8,000-$12,000 |

| Quarterly Treatment | Upholstered items | Specialist contractor | 30 min/piece | $10,000-$15,000 |

| Annual Assessment | Complete inventory | Furniture expert | 1 day | $20,000-$30,000 |

Environmental controls significantly impact furniture longevity, with humidity management between 30-50% preventing wood warping and joint failure. UV protection through window treatments prevents fading and material degradation, particularly important for pieces positioned near windows.

Staff training programs ensure consistent application of proper maintenance techniques across all furniture materials and finishes. Specialized training for different material types prevents damage from inappropriate cleaning methods while maximizing cleaning efficiency.

Restoration vs. replacement decisions require careful cost-benefit analysis considering furniture age, repair costs, and revenue impact during room closure. Professional restoration services can often restore high-quality pieces to like-new condition at 30-40% of replacement cost.

Technology integration in maintenance management includes RFID tracking systems, predictive maintenance algorithms, and automated reordering systems for supplies. Smart maintenance platforms optimize scheduling and reduce operational costs while improving furniture performance.

Case Study: Ace Hotel Sustainability Program

Ace Hotel’s furniture lifecycle management program emphasizes repurposing and upcycling, with headboards created from vintage military canvas and 100% organic mattresses. This approach extends furniture lifecycles while reducing replacement costs and supporting brand authenticity.

Conclusion

Hotel furniture selection represents a complex intersection of durability requirements, aesthetic considerations, and financial optimization that demands expertise across multiple disciplines. The fundamental differences between commercial hospitality furniture and residential alternatives encompass material specifications, safety compliance, usage intensity, and maintenance requirements that directly impact guest satisfaction and operational efficiency.

Strategic procurement approaches that prioritize commercial-grade materials, certified suppliers, and comprehensive maintenance programs deliver superior long-term value compared to short-term cost optimization strategies. Investment in high-quality hotel furniture typically generates returns through reduced replacement frequency, lower maintenance costs, and enhanced guest satisfaction that supports premium pricing strategies.

Emerging trends in hotel furniture design emphasize sustainability, technology integration, and flexible functionality that address evolving guest expectations while supporting operational efficiency. Smart furniture solutions, eco-friendly materials, and modular designs represent the future of hospitality furnishing strategies.

Professional guidance from experienced hospitality furniture specialists proves invaluable in navigating complex procurement decisions, material selections, and maintenance protocols. The substantial investment required and long-term operational implications make expert consultation essential for optimizing furniture performance and guest satisfaction.

Ultimately, successful hotel furniture programs balance durability, aesthetics, and cost-effectiveness while supporting brand identity and operational goals. Properties that approach furniture selection strategically create sustainable competitive advantages that translate directly to guest loyalty, operational efficiency, and financial performance.

FAQ Section

What is the typical lifespan difference between commercial and residential furniture in hotel applications?

Commercial-grade hotel furniture typically lasts 7-15 years in hospitality environments, while residential furniture in the same applications may require replacement every 3-5 years. High-quality commercial pieces with proper maintenance can achieve 15-20 year lifespans, significantly outperforming residential alternatives. The extended lifespan results from commercial-grade construction, superior materials, and reinforced joinery systems designed specifically for intensive use patterns. Proper maintenance protocols can extend these lifespans by an additional 40-60%, making commercial furniture a superior long-term investment despite higher initial costs.

How much should hotels budget for furniture per room based on property classification?

Hotel furniture budgets vary significantly by property classification and target market positioning. Economy hotels typically allocate $8,000-$12,000 per room, midscale properties budget $12,000-$20,000 per room, upscale hotels invest $20,000-$35,000 per room, and luxury properties often exceed $35,000-$50,000 per room. These figures include all FF&E components including furniture, fixtures, lighting, and equipment. Procurement timing and volume commitments can achieve 10-20% cost savings, while custom design elements may increase budgets by 25-40% above standard ranges.

What safety standards must commercial hotel furniture meet?

Commercial hotel furniture must comply with comprehensive safety standards including CAL 117-2013 for upholstery flammability, ASTM guidelines for structural integrity, and ADA requirements for accessibility. Fire safety compliance requires flame-resistant materials and treatments, while structural standards ensure furniture can withstand commercial usage patterns. International properties may require additional certifications such as EN standards in Europe or JIS standards in Japan. Third-party testing and certification documentation ensure compliance and reduce liability risks for hotel operators.

How do material choices impact long-term maintenance costs for hotel furniture?

Material selection directly impacts maintenance requirements and long-term operational costs. Solid hardwood furniture requires moderate maintenance but offers 15-20 year lifespans, while high-pressure laminates need minimal care and provide excellent durability. Commercial-grade upholstery with stain-resistant treatments reduces cleaning time and extends replacement cycles. Poor material choices can increase maintenance costs by 200-300% while requiring more frequent replacement. Quality materials with protective finishes typically reduce annual maintenance costs by $500-$1,500 per room while improving guest satisfaction scores.

What are the key differences between custom and standard hotel furniture procurement?

Custom hotel furniture involves original design development from initial concepts, offering unlimited personalization but requiring 16-24 week lead times and 25-50% cost premiums. Standard furniture utilizes existing designs with modification options, providing 8-12 week delivery and cost-effective pricing. Custom solutions excel for brand differentiation and unique space requirements, while standard options optimize budget efficiency and delivery reliability. Hybrid approaches combining standard frames with custom finishes balance personalization and cost-effectiveness for many hotel projects.