The success of commercial furniture projects depends not only on product quality but also on sophisticated commercial furniture installation processes and comprehensive global project management capabilities. Modern furniture installation requires precise coordination, advanced logistics systems, and specialized expertise to ensure seamless delivery and setup across diverse commercial environments. The complexity of today’s commercial projects, spanning multiple locations, various furniture types, and tight deadlines, demands professional project management that can navigate regulatory requirements, coordinate with multiple stakeholders, and deliver exceptional results within specified timeframes.

Global project management in commercial furniture installation encompasses everything from initial site assessment and delivery scheduling to final quality inspections and client handover. Leading furniture providers develop comprehensive project management systems that ensure consistent execution regardless of project size, location, or complexity. These systems integrate advanced planning software, real-time communication platforms, and quality control protocols that maintain standards across international projects while adapting to local requirements and regulations.

This comprehensive guide examines the critical components of successful commercial furniture installation, exploring project management methodologies, installation processes, quality assurance systems, and the strategic advantages of partnering with providers who excel in global project management. Understanding these elements enables organizations to select installation partners who can deliver complex projects efficiently while maintaining quality standards and meeting critical deadlines.

Advanced Project Management Systems and Methodologies

Commercial furniture installation success begins with sophisticated project management systems that coordinate multiple phases, stakeholders, and deliverables while maintaining clear communication and accountability throughout the project lifecycle. Leading installation providers implement project management methodologies that break complex installations into manageable phases, establish clear milestones, and provide real-time visibility into project progress for all stakeholders.

The project planning phase involves comprehensive site assessments, detailed scheduling coordination, and risk mitigation planning that addresses potential challenges before they impact project timelines. Professional project managers conduct thorough evaluations of installation sites, identifying structural limitations, access constraints, and coordination requirements with other trades that might affect furniture installation schedules.

Resource allocation in commercial furniture installation requires careful coordination of installation teams, specialized equipment, and delivery schedules that minimize disruption to ongoing operations while ensuring efficient project completion. Advanced project management systems enable real-time adjustment of resource assignments based on changing conditions, unexpected challenges, or accelerated timelines requested by clients.

| Project Management Phase | Key Activities | Deliverables | Timeline |

| Initial Assessment | Site surveys, stakeholder meetings, requirement analysis | Project scope document, timeline proposal | 1-2 weeks |

| Planning and Design | Space planning, furniture selection, delivery coordination | Detailed project plan, installation schedule | 2-3 weeks |

| Procurement and Manufacturing | Order processing, quality control, pre-delivery inspection | Furniture ready for delivery, logistics plan | 4-8 weeks |

| Installation Execution | Delivery coordination, furniture assembly, final inspection | Completed installation, handover documentation | 1-3 weeks |

| Post-Installation Support | Training, warranty activation, ongoing maintenance | User manuals, maintenance schedules, support contacts | Ongoing |

Communication protocols establish clear channels between project managers, installation teams, and client stakeholders, ensuring that all parties remain informed about project progress, potential challenges, and schedule adjustments. Modern project management platforms provide real-time updates, photo documentation, and milestone tracking that enable proactive decision-making and rapid response to changing requirements.

Installation Process Excellence and Coordination

Fast furniture project installation requires sophisticated coordination systems that synchronize delivery schedules, installation sequencing, and quality control processes to achieve maximum efficiency while maintaining exceptional quality standards. Professional installation teams develop detailed workflow processes that optimize productivity while ensuring careful handling of furniture and minimal disruption to surrounding operations.

Site preparation represents a critical phase in commercial furniture installation, involving space clearing, protection of existing fixtures, and establishment of staging areas that support efficient installation workflows. Installation teams coordinate with facility managers to ensure appropriate access arrangements, elevator reservations, and utility requirements are available when needed.

Installation sequencing follows carefully planned workflows that optimize team productivity while ensuring proper assembly and placement of furniture components. Professional installation teams understand the importance of installing larger items first, followed by smaller components and accessories, while maintaining clear pathways for ongoing work and final cleaning processes.

| Installation Category | Typical Installation Time | Team Size Required | Special Requirements |

| Executive Office Suites | 4-6 hours per office | 2-3 installers | Precision placement, technology integration |

| Open Plan Workstations | 2-3 hours per workstation | 4-6 installers | Systematic layout, cable management |

| Conference Room Furniture | 6-8 hours per room | 3-4 installers | Audio/visual coordination, precise alignment |

| Reception Area Furniture | 3-5 hours per area | 2-3 installers | Brand presentation, public safety compliance |

| Specialized Healthcare Furniture | 1-2 hours per piece | 2-4 installers | Infection control protocols, medical standards |

Technology integration during installation ensures that furniture with built-in power, data connectivity, and smart features functions properly within the facility’s infrastructure systems. Installation teams coordinate with IT specialists and electrical contractors to verify proper connections and test all integrated systems before final acceptance.

Case Study: World Top Scientists Forum Conference Centre Shanghai Lingang

Hongye Furniture Group executed a complex installation project for the World Top Scientists Forum Conference Centre in Shanghai Lingang, a prestigious international venue requiring exceptional quality and precision. The installation involved multiple conference rooms, executive offices, and public areas with specialized furniture designed to support high-level scientific conferences and international meetings. The project required coordination with multiple trades, adherence to international safety standards, and completion within tight deadlines to meet the forum’s launch schedule. The installation team developed innovative staging and sequencing approaches that enabled simultaneous work in multiple areas while maintaining quality standards throughout the process.

Quality control during installation involves continuous monitoring of assembly quality, proper placement verification, and functional testing of all furniture components. Professional installation teams use detailed checklists and inspection protocols that ensure each piece meets specified requirements before moving to the next installation phase.

Client coordination throughout the installation process maintains clear communication about progress, addresses any concerns immediately, and ensures that the final installation meets or exceeds client expectations. This includes regular progress updates, prompt resolution of any issues, and comprehensive final walk-throughs that document successful completion of all installation requirements.

Global Coordination and Multi-Location Projects

Global project management capabilities enable commercial furniture providers to coordinate complex installations across multiple locations, time zones, and regulatory environments while maintaining consistent quality standards and efficient communication. International projects require sophisticated coordination systems that address cultural differences, local regulations, and logistical challenges that can significantly impact project success.

Multi-location coordination involves developing standardized processes that can be adapted to local requirements while maintaining overall project coherence and quality consistency. This includes establishing local project management teams, coordinating with regional suppliers and installers, and ensuring compliance with local building codes and safety regulations.

International logistics management addresses the complex requirements of shipping furniture across borders, including customs documentation, import regulations, and coordination with local delivery services. Experienced providers develop relationships with international shipping partners and customs brokers that ensure smooth delivery processes and minimize delays that could impact installation schedules.

| Global Project Complexity | Coordination Requirements | Management Approach | Success Factors |

| Single International Location | Local partnerships, regulatory compliance | Dedicated project manager with local support | Cultural understanding, regulatory expertise |

| Multi-Country Rollout | Standardized processes, regional coordination | Regional project teams with central oversight | Process standardization, communication protocols |

| Ongoing Global Programs | Continuous coordination, vendor management | Dedicated global account management | Long-term partnerships, systematic processes |

| Emergency International Projects | Rapid deployment, expedited logistics | Crisis management protocols | Flexible resources, established networks |

Cultural adaptation in global project management ensures that installation approaches respect local customs, work practices, and communication styles while maintaining overall project standards. This includes understanding local holidays, work schedules, and business practices that might affect project timelines and coordination requirements.

Case Study: Zhuhai Hilton Hotel (DoubleTree by Hilton Zhuhai Hengqin)

Hongye Furniture Group managed the comprehensive furniture installation for DoubleTree by Hilton Zhuhai Hengqin, an international hospitality project requiring coordination with Hilton’s global standards and local construction teams. The project involved guest room furniture, public area seating, restaurant furniture, and specialized hotel amenities across multiple floors and building phases. The installation required adherence to Hilton’s international quality standards while coordinating with local contractors, regulatory inspections, and the hotel’s pre-opening timeline. The project management team developed bilingual communication protocols and coordinated with Hilton’s international project management systems to ensure seamless integration with the hotel’s opening schedule.

Regulatory compliance across different countries requires comprehensive understanding of local building codes, safety regulations, and import requirements that affect furniture installation projects. Global project managers maintain current knowledge of international regulations and work with local experts to ensure full compliance in all project locations.

Time zone management in global projects involves establishing communication schedules that accommodate different time zones while ensuring timely decision-making and problem resolution. This includes scheduling regular project updates, establishing emergency communication protocols, and using project management platforms that provide real-time visibility regardless of geographical location

Quality Assurance and Post-Installation Support

Quality control systems in commercial furniture installation ensure that every piece meets specified requirements and functions properly within its intended environment. Comprehensive quality assurance processes begin with pre-installation inspections and continue through final client acceptance, providing multiple checkpoints that identify and resolve any issues before they affect project success.

Pre-installation quality checks involve thorough inspection of all furniture components before delivery to installation sites, verifying that products meet specifications, show no damage from shipping, and include all necessary components for proper assembly. This proactive approach prevents installation delays and ensures that only perfect products reach client locations.

Installation quality monitoring includes ongoing supervision of assembly processes, verification of proper installation techniques, and immediate correction of any issues identified during the installation process. Professional installation supervisors use detailed quality checklists and photographic documentation to ensure consistent standards across all project phases.

| Quality Control Phase | Inspection Points | Documentation Requirements | Correction Protocols |

| Pre-Delivery Inspection | Product condition, completeness, specifications | Quality certification, shipping documentation | Return to manufacturer, replacement orders |

| Installation Monitoring | Assembly quality, placement accuracy, function testing | Progress photos, quality checklists | Immediate correction, supervisor intervention |

| Final Inspection | Overall quality, client requirements, function verification | Completion certificates, client sign-off | Final adjustments, warranty activation |

| Post-Installation Follow-up | User satisfaction, performance monitoring, maintenance needs | Client feedback, performance reports | Corrective actions, ongoing support |

Client training and handover processes ensure that facility managers and users understand proper furniture operation, maintenance requirements, and warranty coverage. Comprehensive handover includes operation manuals, maintenance schedules, and contact information for ongoing support services.

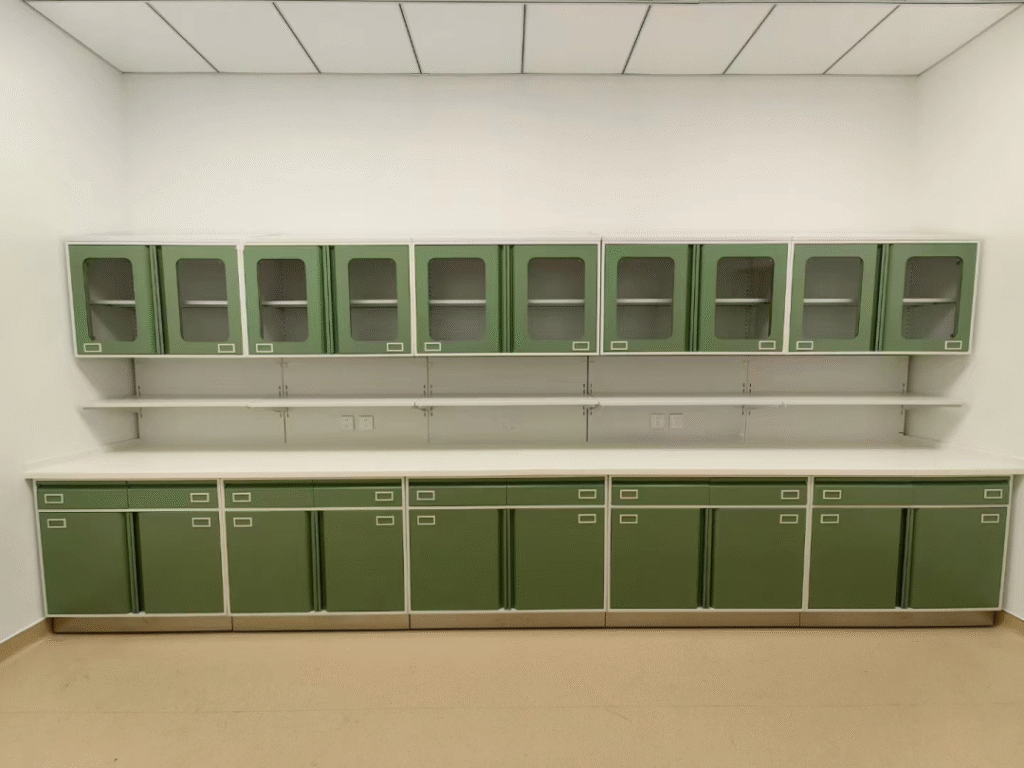

Case Study: Nan’an Hospital Healthcare Furniture Installation

Hongye Furniture Group completed a 17.5 million yuan healthcare furniture installation project for Nan’an Hospital, involving 11 functional areas with specialized medical furniture requirements. The installation required adherence to strict healthcare infection control protocols, coordination with medical equipment installation, and compliance with healthcare facility regulations. The quality assurance process included specialized cleaning protocols for healthcare environments, verification of antimicrobial surface treatments, and comprehensive testing of all integrated medical systems. Post-installation support included training for hospital staff on furniture maintenance protocols and establishment of ongoing maintenance schedules that support the hospital’s infection control requirements.

Warranty management systems provide comprehensive coverage for installed furniture while establishing clear procedures for addressing any post-installation issues. Professional providers maintain detailed warranty databases and rapid response systems that ensure prompt resolution of any warranty claims while minimizing disruption to client operations.

Ongoing support services extend beyond initial installation to provide maintenance guidance, replacement part availability, and future expansion support that helps clients maximize their furniture investment value. This includes periodic facility assessments, preventive maintenance recommendations, and coordination of any future furniture additions or modifications.

Technology Integration and Digital Project Management

Digital project management platforms revolutionize commercial furniture installation by providing real-time visibility, automated scheduling, and comprehensive documentation that improves efficiency while ensuring accountability throughout the project lifecycle. Modern installation providers leverage advanced software systems that integrate planning, execution, and quality control processes into unified platforms accessible to all project stakeholders.

Real-time project tracking enables clients and project managers to monitor installation progress through live updates, photographic documentation, and milestone completion notifications. These systems provide transparency that builds confidence while enabling proactive management of any issues that might affect project timelines or quality outcomes.

Mobile technology integration empowers installation teams with tablet-based systems that provide access to installation instructions, quality checklists, and immediate communication with project managers. This technology eliminates paperwork, reduces errors, and enables instant documentation of installation progress and any issues requiring attention.

Conclusion

Commercial furniture installation success requires sophisticated global project management capabilities that coordinate complex logistics, manage diverse stakeholder requirements, and deliver exceptional quality within challenging timelines. The integration of advanced project management systems, professional installation processes, comprehensive quality assurance, and digital technology platforms creates installation capabilities that exceed client expectations while minimizing project risks.

Organizations planning commercial furniture projects should prioritize providers who demonstrate proven global project management expertise, comprehensive quality control systems, and advanced technology integration that ensures successful project outcomes. The complexity of modern commercial environments demands installation partners who can navigate regulatory requirements, coordinate with multiple trades, and deliver consistent quality across diverse project types and locations.

The future of commercial furniture installation continues evolving toward greater digitization, automated processes, and enhanced client communication that improves efficiency while maintaining the personal attention required for successful project outcomes. Professional furniture installation providers who invest in advanced project management capabilities position themselves to lead market development while delivering exceptional value to clients with complex installation requirements.

Success in today’s competitive commercial furniture market requires providers who understand that exceptional installation capabilities differentiate leading companies from competitors, creating lasting client relationships and supporting business growth through demonstrated excellence in project execution and client satisfaction.

Frequently Asked Questions

What factors should organizations consider when evaluating commercial furniture installation providers?

Organizations should evaluate installation providers based on their project management systems, installation team qualifications, quality control processes, and track record of successful project completion. Key considerations include the provider’s ability to coordinate complex logistics, manage multiple stakeholders, and maintain quality standards under pressure. References from similar projects provide valuable insights into actual performance, while facility tours and team interviews demonstrate capabilities and professionalism. Technology integration capabilities, insurance coverage, and warranty support also represent critical evaluation factors. The provider’s experience with specific project types, regulatory environments, and client industries helps ensure they understand unique requirements and can deliver appropriate solutions within specified timeframes and budgets.

How do global project management capabilities benefit multi-location furniture installations?

Global project management provides standardized processes that ensure consistent quality across different locations while adapting to local requirements and regulations. Experienced providers maintain international networks of qualified installation teams, logistics partners, and regulatory experts that enable efficient coordination across time zones and cultural boundaries. Centralized project management systems provide real-time visibility into all locations while local teams handle day-to-day execution details. This approach reduces costs through economies of scale, improves quality through standardized procedures, and accelerates timelines through parallel execution capabilities. Global providers also offer ongoing support services that maintain consistency over time and facilitate future expansion or modification projects across multiple locations.

What role does technology play in modern commercial furniture installation projects?

Technology revolutionizes installation projects through digital project management platforms that provide real-time tracking, automated scheduling, and comprehensive documentation capabilities. Mobile devices enable installation teams to access current information, update project status, and communicate immediately with project managers and clients. Advanced scheduling software optimizes resource allocation and adapts to changing conditions while maintaining overall project coordination. Photography and documentation systems create comprehensive project records that support quality control and client acceptance processes. Technology also enables predictive analytics that help providers optimize their processes and improve future project outcomes while providing clients with detailed performance metrics and outcome verification.

How do installation providers ensure quality control during complex commercial projects?

Quality control systems include multiple inspection phases from pre-delivery verification through final client acceptance, with detailed checklists and documentation requirements at each stage. Professional installation supervisors monitor assembly processes continuously, while project managers conduct regular quality audits and client communication sessions. Advanced providers use photographic documentation, digital inspection systems, and real-time quality reporting that enables immediate correction of any issues. Training programs ensure installation teams understand quality standards and proper procedures, while ongoing certification maintains skill levels. Post-installation follow-up verifies long-term performance and client satisfaction while identifying any warranty issues that require attention.

What are the typical timelines for different types of commercial furniture installation projects?

Installation timelines vary significantly based on project size, complexity, and specific requirements, but typical ranges include small office projects requiring 1-3 days, medium corporate installations needing 1-2 weeks, and large campus or multi-building projects extending 4-8 weeks. Healthcare installations often require additional time for compliance verification and specialized procedures, while hotel projects may involve phased approaches that accommodate ongoing operations. Factors affecting timelines include site access limitations, coordination with other trades, custom furniture manufacturing requirements, and client scheduling constraints. Experienced providers develop realistic timeline estimates during planning phases and maintain flexibility to accommodate changing conditions while meeting critical milestone requirements.

How do installation providers handle coordination with other trades and construction activities?

Professional installation providers develop coordination protocols that integrate with overall construction schedules while protecting furniture and ensuring safety during multi-trade environments. This includes scheduling coordination meetings, establishing clear access requirements, and implementing protection procedures for completed installations. Communication systems ensure all trades understand furniture installation requirements and potential conflicts, while project managers maintain regular contact with general contractors and other specialists. Advanced providers use construction management software that integrates with overall project schedules and provides real-time updates on progress and potential conflicts. Safety protocols ensure compliance with construction site requirements while protecting installation teams and furniture during complex coordination scenarios.