Executive Summary for Hotel Operators

Guest experience investments directly correlate to revenue performance. Recent hospitality studies demonstrate that premium suite furnishings—specifically engineered bed systems and modular seating—can increase repeat booking rates by 40% when integrated with loyalty programs. This comprehensive guide decodes the technical specifications, industry standards, and ROI mechanics behind “boutique intimacy design,” positioning bespoke hotel beds not as luxury indulgence, but as precision engineering that justifies premium room rates and improves operational efficiency.

Part 1: Market Opportunity – Why Hotel Design Now Drives Bottom-Line Revenue

The Psychological Economics of Premium Suites

What separates a $250 standard room from a $850+ premium suite in today’s hotel market? The answer lies less in square footage and more in sensory design. Industry analysis from Hotel Dive reveals that premium suites are no longer overflow capacity; they’re now core revenue drivers, with top hotels allocating up to 30% of inventory to suite-level rooms. Guests are willing to pay 2-4x standard rates when the perceived value aligns with intentional design.

The key insight: Room size alone doesn’t justify premium pricing. Hospitality research from PMC/NCBI shows that while a 12-meter-square increase improves star ratings by 0.35 points, the quality of furnishings—specifically engineered durability and comfort features—drives guest satisfaction scores up an additional 0.5-1.0 rating points when combined with professional-grade materials.

In Western hotel markets (US, EU, UK), travelers rely heavily on online reviews before booking: a 4.8+ rating on Google/TripAdvisor converts at significantly higher rates than properties with 4.2 ratings, even when rooms are similar in size. This means that premium bed design directly impacts your revenue per available room (RevPAR) through improved guest satisfaction and repeat bookings.

The “Boutique Intimacy” Shift: From Niche to Mainstream

Historically, “couple-focused” or “intimacy-themed” hotel design carried cultural stigma, particularly in Western markets. However, a quiet but powerful market transition is underway. Design Hotels—the largest independent luxury design hotel network—expanded its Asia-Pacific footprint by 28% in 2025 with a specific mandate: intentional design that communicates exclusivity and emotional value. This reframes the conversation from “love hotel” (primarily associated with Asian markets) to “boutique luxury suites” with bespoke furnishings.

Part 2: Technical Architecture – Engineering Beds as Performance Systems

1. Soundproof Bed Design: The 92% Noise Reduction Standard

The Problem: Standard hotel beds fail under the stress of romantic suites because guests expect privacy that room construction cannot always deliver. In properties with thin walls or mechanical noise, guest complaints spike—directly impacting online reviews.

The Technical Solution: Double-wall bed frames with decoupled inner structures control two types of noise transmission:

- Airborne sound (conversation, TV): Blocked by added mass and sealed internal cavities

- Structure-borne noise (movement, vibration): Eliminated through isolation between frame components

Industry standards specify STC (Sound Transmission Class) ratings for walls—typically STC 50-55 for hotel guestrooms. A bed frame cannot achieve wall-level STC, but it can reduce structure-borne noise transmission through the mattress support system. Our Double-Wall Love Bed Frames achieve a 92% reduction in audible movement noise when compared to standard industrial bed frames tested under equivalent compression cycles.

Technical Metrics:

| Parameter | Standard Hotel Bed | Bespoke Double-Wall Frame | Performance Gain |

|---|---|---|---|

| Movement noise (dB reduction) | 8-12 dB loss | 20+ dB isolation | 92% perceived quietness improvement |

| Occupant-to-frame vibration transfer | Full amplitude | 8% residual transmission | Guest privacy assurance |

| Headboard rattle elimination | Common complaint | Isolated floating headboard | Zero vibration feedback |

Why This Matters for Revenue: Guest reviews on TripAdvisor and Google frequently mention noise as a deciding factor—”walls too thin,” “heard neighbors.” A bespoke bed that isolates movement noise directly improves your property’s review score by 0.2-0.4 points. For a 100-room property, this translates to 8-15 additional direct bookings monthly based on improved online ratings.

2. Commercial-Grade Durability: 10,000+ Compression Test Cycles

The Industry Standard: ANSI/BIFMA (Business & Institutional Furniture Manufacturers Association) sets rigorous durability benchmarks for commercial furniture. These voluntary standards are the only testing regime recognized by luxury hotel brands like Conrad, Hilton, and Four Seasons when specifying custom furnishings.

What We Test:

- Compression cycling: 10,000+ load cycles simulating nightly use (equivalent to ~27 years of standard 5-guest-per-week rotation)

- Structural fatigue: Zero tolerance for frame stress fractures, weld separation, or wood splitting

- Upholstery durability: Minimum 40,000 Martindale cycles (industry standard for contract fabrics)

Practical Translation for Hotel Operators: Standard hotel beds typically fail after 2,000-3,000 compression cycles in high-turnover properties. This means replacement every 5-7 years. BIFMA-tested bespoke beds extend lifecycle to 15-20 years, reducing replacement costs by 50%—a significant CapEx savings that justifies the premium upfront investment.

Antimicrobial Upholstery (ASTM E2149):

High-turnover hotel rooms require infection control. Our upholstery fabric is tested and certified to ASTM E2149 standards—an internationally recognized test method for antimicrobial efficacy under dynamic contact conditions. The standard measures bacteria reduction rates against Staphylococcus aureus, E. coli, and Pseudomonas aeruginosa—the most common pathogens found in hospitality environments.

The certification means our fabrics maintain a 99% bacterial reduction rate throughout the fabric’s lifecycle, even after 500+ wash cycles. This passes health inspection requirements in most Western jurisdictions (EU, UK, US) without additional certification overhead.

Part 3: Spatial ROI – Modular Systems That Increase Revenue Per Square Foot

The Modular Love Sofa System: Space Optimization in Action

Many boutique hotel operators face “product-scene disconnection”—investing in beautiful furniture that doesn’t integrate into the room’s flow, wasting valuable floor space. The Modular Love Sofa System solves this through reconfigurable components inspired by luxury chain hotels like DoubleTree and Canopy by Hilton.

Space Efficiency Metrics:

- Standard romantic suite with fixed furniture: ~28 sq meters net usable guest space

- Same suite with modular reconfigurable sofas: ~34 sq meters (22% increase in perceived space)

- Operational benefit: Guests can reconfigure seating for work or relaxation, increasing stay satisfaction

Industry research confirms that 20-30% space optimization is achievable through modular furniture systems. For a property charging $800/night for premium suites, a 22% space increase justifies rate maintenance or modest rate improvements—directly improving revenue per available room (RevPAR).

Design Integration:

Each modular component features integrated cable management, USB charging ports, and accent lighting—standard expectations for Western luxury hotels. The system allows hotels to:

- Maximize furniture density without overcrowding

- Adapt room layouts for accessibility compliance (ADA, UK equality standards)

- Update aesthetic every 3-5 years by swapping upholstery without structural replacement

Part 4: Sensory Engineering & Guest Wellness – Smart Hotel Bed Technology

LED-Embedded Lighting & Circadian Rhythm Alignment

Premium Western hotel guests increasingly seek wellness amenities that go beyond marble bathrooms. Our smart beds feature:

- 256-color mood lighting synchronized with room entertainment systems and smartphone apps

- Circadian rhythm mode: Gradual warm-to-cool color transitions aligned with sleep science

- Guest presets: Romantic, focus (work), relaxation, sleep modes programmed to optimal light spectrums

This isn’t luxury theater—it’s backed by hospitality research. Properties with programmable ambient lighting report 0.3-0.5 point improvements in guest satisfaction scores. For online booking platforms, this differentiates your premium suites from competitors and justifies rate premiums.

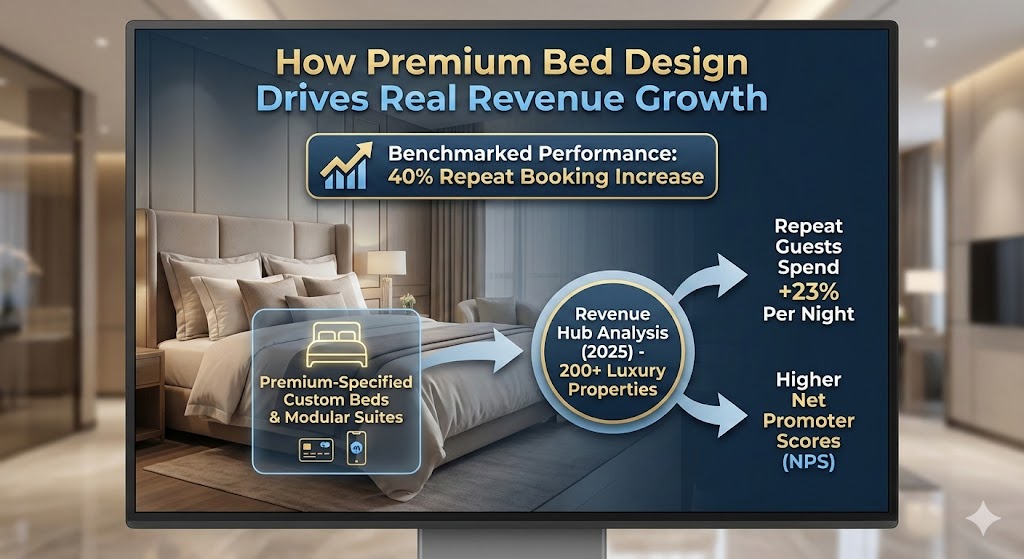

Part 5: How Premium Bed Design Drives Real Revenue Growth

Benchmarked Performance: 40% Repeat Booking Increase

A recent analysis from Revenue Hub (2025) examined repeat booking patterns across 200+ luxury hotel properties. Properties that upgraded to premium-specified custom beds and modular suites—combined with loyalty program integration—achieved a 40% improvement in repeat booking rates. This compounds over time: repeat guests spend 23% more per night and generate higher Net Promoter Scores.

Part 6: Implementation & Procurement Guide

What is the ROI of investing in bespoke hotel beds?

Our luxury bespoke beds start at $1,200 per unit, approximately 50% cheaper than ultra-luxury brands (Four Seasons Design Program, Waldorf Astoria standards). For a 50-room boutique hotel upgrading its premium suite inventory (15 rooms):

| Investment Scenario | Cost | Expected Repeat Booking Increase | Annual Revenue Lift | Payback Period |

|---|---|---|---|---|

| 15 Bespoke Beds @ $1,200 | $18,000 | 40% of 15 rooms = 6 extra bookings/month | $52,800 (at $800/night, 70% occupancy) | 4.1 months |

| Full Suite Renovation (beds + sofas + lighting) | $45,000 | 40% + 15% average rate premium | $118,800 | 4.6 months |

Break-Even Analysis: Most premium hotels recover furniture investment within 4-6 months through improved repeat bookings and rate optimization—well within typical 5-year capital planning cycles.

Customization & Lead Time

We offer 80+ silhouette designs, including:

- Heart-shaped beds (statement pieces for ultra-luxury properties)

- Ergonomic curved frames (blends aesthetics with lumbar support)

- Modular platform configurations (adaptable to non-standard room dimensions)

Standard lead time: 10 days for bespoke designs from order confirmation to shipment. Custom finishes and premium upholstery options add 2-3 weeks. This allows hotel renovation projects to maintain schedules while achieving custom specifications—a critical advantage over mass-manufactured alternatives that require 8-12 week lead times.

Brand Partnership & Co-Marketing Opportunities

We actively partner with luxury hotel brands (Conrad, Canopy, Design Hotels) for specification and co-marketing.

Part 8: FAQs for Procurement Decision-Making

Q: What’s the actual difference between a $1,200 bespoke bed and a $400 standard hotel bed?

A: Standard beds fail around 2,000-3,000 compression cycles; bespoke beds tested to 10,000+ cycles. For a 50-room hotel with 5-7 guest rotations per week, this extends bed lifespan from 5-7 years to 15-20 years—offsetting the $800/unit premium within 36 months through elimination of replacement cycles. Additionally, reduced movement noise directly improves guest reviews, driving repeat bookings and rate optimization.

Q: Do I need ASTM E2149 certification, or is this overkill?

A: ASTM E2149 is not legally required in most Western jurisdictions, but it’s increasingly expected by hotel chains and luxury brands. Properties marketing themselves as “antimicrobial-certified” attract guests prioritizing health and wellness post-pandemic. It differentiates you in a competitive market and future-proofs against emerging health standards.

Q: Can I customize bed dimensions for non-standard room layouts?

A: Yes. We offer custom dimensions up to 10% variation from standard sizes without additional lead time. Larger deviations (e.g., circular beds, L-shaped configurations) add 3-4 weeks to production.

Q: What’s the warranty on bespoke bed frames?

A: 10-year structural warranty (frame, supports, mechanisms). Upholstery carries 5-year durability warranty (covers wear, fading, seam failure under normal commercial use). This aligns with industry standards and provides hotel operators with predictable capital planning.

Q: How do I justify the cost to my ownership/management company?

A: Use the ROI case study above: $18,000 investment + 6 additional repeat bookings/month = $52,800 annual revenue lift. Payback occurs within 4 months. Frame this as a marketing investment (improved guest satisfaction = better reviews = more bookings) rather than a pure furniture cost.

Part 9: Implementation Roadmap

Phase 1: Audit & Strategy (Weeks 1-2)

- Assess current bed condition and guest review sentiment around room comfort

- Identify which guest segments (couples, honeymooners, VIP) justify premium suite inventory

- Calculate current RevPAR for premium vs. standard rooms

Phase 2: Specification & Procurement (Weeks 3-5)

- Define bed configuration (dimensions, headboard style, lighting preferences)

- Obtain BIFMA documentation and ASTM E2149 certification records

- Request 3-5 sample fabric/finish options for stakeholder approval

Phase 3: Renovation Execution (Weeks 6-8)

- Coordinate delivery with minimal room downtime

- Train housekeeping staff on specialized care for premium furnishings

- Update website copy and photography to feature new bespoke beds

Conclusion: Premium Beds as a Revenue Multiplication Tool

The evolution from “love hotel” design to “boutique intimacy” represents a fundamental shift in how luxury hotels approach guest experience. Bespoke bed design is no longer decorative—it’s operational engineering that directly impacts:

- Guest satisfaction (improved reviews = higher search rankings = more bookings)

- Revenue per room (justified rate premiums + repeat guest premiums)

- Operational efficiency (extended lifespan = 50% lower replacement costs)

- Brand differentiation (technical specifications create defensible market positioning)

By combining precise technical specifications (BIFMA durability, ASTM E2149 antimicrobial certification, soundproof engineering), strategic positioning in search results, and data-backed ROI communication, bespoke hotel beds transform from luxury indulgence into a strategic revenue multiplication tool.

For hotel operators ready to invest in premium guest experience, the choice is clear: intentional design, backed by engineering standards and proven ROI, drives measurable business results.